OSHA Guide – Cranes and Derricks in Construction

MENU

- Introduction

- Employer Responsibilities

- Section 1400 – Scope

- Section 1401 – Definitions

- Section 1402 – Ground Conditions

- Sections 1403-1406 – Assembly and Disassembly

- Sections 1407-1411 – Power Lines

- Section 1412 – Inspections (with Section 1435(f)-Tower Crane Inspections) and Section 1436(p)-Derricks Inspections)

- Section 1413 – Wire Rope Inspection

- Section 1414 – Wire Rope – Selection and Installation Criteria

- Sections 1415 Safety Devices & 1416 Operational Aids

- Section 1417 – Operation

- Section 1418 – Authority to Stop Operation

- Section 1419-1422 – Signals

- Section 1423 – Fall Protection

- Section 1424 – Work Area Control

- Section 1425 – Keeping Clear of the Load

- Section 1426 – Free Fall and Controlled Load Lowering

- Section 1427 – Operator Qualification and Certification

- Section 1428 – Signal Person Qualifications

- Section 1429 – Qualifications of Maintenance & Repair Employees

- Section 1430 – Training

- Section 1431 – Hoisting Personnel

- Section 1432 – Multiple-Crane/Derrick Lifts

- Section 1433 – Design, Construction and Testing

- Section 1434 – Equipment Modifications

- Section 1435 – Tower Cranes

- Section 1436 – Derricks

- Section 1437 – Floating Cranes/Derricks and Land Cranes/Derricks on Barges

- Section 1438 – Overhead & Gantry Cranes

- Section 1439 – Dedicated Pile Drivers

- Section 1440 – Sideboom Cranes

- Section 1441 – Equipment with a Rated Hoisting/Lifting Capacity of 2,000 Pounds or Less

- Directory of States with Approved Occupational Safety and Health Programs

- Workers’ Rights

- OSHA Assistance, Services and Programs

- OSHA Regional Offices

- NIOSH Health Hazard Evaluation Program

Sections 1407-1411 – Power Lines

Danger - High Voltage

Electrocutions caused by a crane, load, or load line contacting a power line have caused numerous fatalities. To prevent such accidents in the future, the standard contains detailed, systematic procedures that employers must follow when operating cranes near power lines. These procedures are designed to (1) prevent equipment from making electrical contact with power lines; and (2) protect workers in the event that such contact occurs.

NOTE: Special rules apply to work covered by 29 CFR, Subpart V, Power Transmission and Distribution. This information does not cover Subpart V work.

The First Step - Could the Crane Get Closer Than 20 Feet to a Power Line?

Keeping a safe distance from power lines is the key to preventing power line accidents. Therefore, the first step you must take when planning to operate a crane on a site where a power line is present is to identify the crane’s work zone and use that work zone to determine how close it could come to the power line. If you determine that no part of the crane, load, or load line could get closer than 20 feet to a power line, no further precautions are required. If the initial plan for the crane’s use changes during the project, you must reevaluate whether the equipment could get closer than 20 feet to the power line.

Note: If the line’s voltage is over 350,000 volts, a 50-foot, rather than 20-foot, minimum clearance must be maintained. This assumes that the voltage is less than 350,000 volts and uses the 20-foot clearance distance.

There are two ways to identify the work zone and use it to determine whether the equipment could get closer than 20 feet to the power line. First, if the equipment (crane, load, load line, or rigging) could not get closer than 20 feet to the line even if the crane is operated at its maximum working radius, the 20- foot requirement is satisfied. Alternatively, you may establish a work zone by establishing boundaries (using flags or a device such as a range limit device or range control warning device) that are more than 20 feet from the power line and prohibiting the operator from operating the equipment past those boundaries.

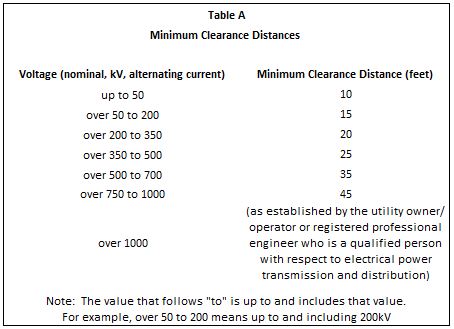

Alternative to 20-foot Clearance (Table A)

If you know the line’s voltage, you may use the minimum clearance distance in Table A in lieu of 20 feet. Table A provides:

One way to determine the line’s voltage is to ask the line’s owner or operator. The utility must respond to such a voltage inquiry within two working days.

If you use Table A to determine the minimum clearance distance, you must determine whether any part of the crane, load, or load line could get closer than the Table A distance to a power line if the equipment is operated up to its maximum working radius in the work zone.

If you determine that part of the crane, load, or load line could come closer to the power line than the required minimum clearance distance (either 20 feet or the Table A clearance), you must either de-energize and ground the line or take specified steps to maintain the required minimum clearance distance. These options will now be discussed.

De-energize and Ground

De-energizing and visibly grounding the line will protect against electrocution and avoid the need for additional precautions. However, the employer must rely on the power line’s owner or operator to take these steps, and utilities are generally unwilling to de-energize their lines because doing so will cut off service to their customers. As a result, this precaution will usually not be available.

You must assume that all power lines are energized unless the utility owner/operator confirms that the power line has been and continues to be de-energized and the line is visibly grounded at the work site.

Steps You Must Take to Maintain the Required Minimum Clearance Distance

You must take all of the following steps.

- Conduct a planning meeting with the crane operator and the other workers who will be in the area of the equipment or load to review the location of the power line(s), and the steps that will be implemented to prevent encroachment/ electrocution

- If tag lines are used, they must be non-conductive

- Erect and maintain an elevated warning line, barricade, or line of signs equipped with flags or similar high-visibility markings at the minimum clearance distance. If the operator cannot see the elevated warning line, a dedicated spotter must be used to signal the operator that the crane is passing the marked line

In addition, you must use at least one of the following precautions:

- A dedicated spotter (a worker whose only duty is to observe the clearance between the equipment and the line) who is in continuous contact with the operator

- A proximity alarm set to give the operator sufficient warning to prevent encroachment

- A device that automatically warns the operator when to stop movement, such as a range control warning device. Such a device must be set to give the operator sufficient warning to prevent encroachment

- A device that automatically limits the crane’s range of movement, set to prevent encroachment

- An insulating link/device installed between the end of the load line and the load

If you use a dedicated spotter, the dedicated spotter must be able to judge the distance between the equipment and the line and inform the operator if the equipment is getting too close to the line. Therefore, the spotter must:

- Be equipped with a visual aid (such as a clearly visible line painted on the ground or a clearly visible line of stanchions) to assist in identifying the minimum clearance distance

- Be positioned to effectively gauge the clearance distance

- Where necessary, use equipment that enables the spotter to communicate directly with the operator

- Give timely information to the operator so that the required clearance distance can be maintained

- Be trained to be able to perform his/her duties effectively

Operation Below Power Lines Generally Prohibited

No part of the equipment, load line, or load (including rigging and lifting accessories) is allowed below a power line unless the:

- employer has confirmed that the utility owner/operator has de-energized and visibly grounded the power line at the work site, or

- highest point of the equipment’s boom, even if completely extended and vertical, will be more than the required minimum distance from the power line

Employee Training

If the equipment contacts a power line, death or injury may be avoided if the workers in and on the crane know and understand the steps they can take to protect themselves. In general, the crane operator and any other person on the crane will be safe as long as they remain on the crane. The greatest danger is faced by a person who simultaneously touches both the crane and the ground, but a person who is near, but not touching, the crane can also suffer electric shock. To ensure that employees have the information they need to protect themselves, you must train each operator and crew member assigned to work with the equipment on how to avoid electrocution in the event the equipment contacts a power line. Such training must include:

- Information regarding the danger of electrocution if a person simultaneously touches the equipment and the ground

- The importance to the operator’s safety of remaining inside the cab except where there is an imminent danger of fire, explosion, or other emergency that necessitates leaving the cab. The safest means of evacuating from equipment that may be energized

- The danger of the potentially energized zone around the equipment (step potential)

- The need for crew in the area to avoid approaching or touching the equipment and the load

- Safe clearance distance from power lines

- The limitations of an insulating link/device, proximity alarm, and range control (and similar) device, if used

- How to properly ground equipment and the limitations of grounding

Assembling a Crane Near a Power Line

The precautions described above for crane operations must also be taken when assembling or disassembling a crane near a power line. Under no circumstances may a crane be assembled or disassembled beneath an energized power line.

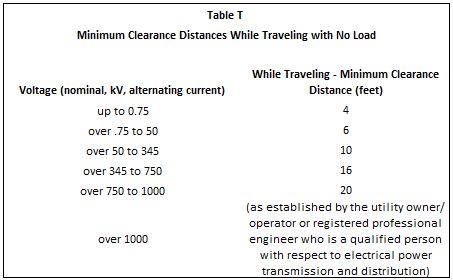

Precautions for Moving Equipment

A crane traveling with a load must comply with the minimum clearance distance and associated precautions listed above. If the crane is traveling with no load, the following clearance distances must be maintained.

In determining whether the equipment will maintain the required clearance distance, you must take into account the effects of speed and terrain on the equipment’s movement (including movement of the boom/mast). In addition, if any part of the equipment can get closer than 20 feet to the line, you must use a dedicated spotter to observe the clearance and signal the operator in order to keep the required minimum clearance.

Limited Exception to Mandatory Minimum Clearance

In some circumstances, it is impossible to perform a required lift while staying the required minimum distance from a power line. The standard provides a limited exception for such circumstances that allows operations closer than the minimum distance. However, it requires additional precautions due to the extreme danger of operating so close to a power line.

Before using this exception, you must determine that specific work required to complete the project cannot be performed while maintaining the Table A clearance. In making this determination, you must consider whether an alternative method of performing the lift, such as re-positioning the crane or the load, will enable you to maintain the required minimum distance. If you have decided that it is absolutely necessary to operate closer than the required minimum distance, you must consult the utility that owns or operates the line to determine whether it is feasible to de-energize and ground or relocate the line. Only if de-energizing/grounding or relocation is not feasible may you operate closer than the Table A distance to an energized line. In such a case, you must take the following precautions to protect workers:

First: determine an absolute minimum clearance

You must have the power line owner/operator or a registered professional engineer who is a qualified person with respect to electrical power transmission and distribution determine the minimum clearance distance that must be maintained to prevent electrical contact in light of the on-site conditions. The factors that must be considered in making this determination include, but are not limited to: conditions affecting atmospheric conductivity; time necessary to bring the equipment, load line, and load (including rigging and lifting accessories) to a complete stop; wind conditions; degree of sway in the power line; lighting conditions; and other conditions affecting the ability to prevent electrical contact.

Second: hold a planning meeting

You must hold a planning meeting with the utility owner/ operator (or registered professional engineer who is a qualified person with respect to electrical power transmission and distribution) to determine the procedures that will be followed to prevent electrical contact and electrocution.

Third: use protective procedures

The procedures required by the standard and any additional procedures developed at the planning meeting must be followed. The following procedures are required by the standard and must be followed without exception:

- If the power line is equipped with a device that automatically re-energizes the circuit in the event of a power line contact, before the work begins, the automatic re-closing feature of the circuit interrupting device must be made inoperative if the design of the device permits

- A dedicated spotter who is in continuous contact with the operator must be used to ensure that the equipment does not breach the minimum clearance. The requirements for a dedicated spotter are discussed above

- An elevated warning line, or barricade (not attached to the crane), in view of the operator (either directly or through video equipment), equipped with flags or similar high-visibility markings, must be erected

- An insulating link/device must be installed at a point between the end of the load line (or below) and the load. (NOTE: certain safety procedures or devices may be substituted for a Nationally Recognized Testing Laboratory-approved insulating link during an interim time period

- All employees who may come in contact with the equipment, the load line, or the load (except operators located on the equipment) must be insulated or guarded from the equipment, the load line and the load by wearing insulating gloves rated for the voltage involved or using another effective means of insulating them from the equipment

- Non-conductive rigging must be used

- If the equipment is equipped with a device that automatically limits range of movement, it must be used and set to prevent any part of the equipment, load line, or load (including rigging and lifting accessories) from breaching the minimum approach distance

- Any tag line that is used must be of the non-conductive type

- Barricades forming a perimeter at least 10 feet away from the equipment must be erected to prevent unauthorized personnel from entering the work area. In areas where obstacles prevent the barricade from being at least 10 feet away, the barricade must be as far from the equipment as feasible

- Workers other than the operator must be prohibited from touching the load line above the insulating link/device and crane. The operator is excluded from this requirement because, while on the equipment, the operator is, in effect, touching the load line above the insulating link/device. However, if the operator is remotely operating the equipment from the ground, he/she must use either wireless controls that isolate the operator from the equipment or insulating mats that insulate the operator from the ground

- Only personnel essential to the operation are permitted in the area of the crane and load.

- The equipment must be properly grounded

- Insulating line hose or cover-up must be installed by the utility owner/operator except where such devices are unavailable for the line voltages involved

- Each operator and crew member assigned to work with the equipment must be trained in the topics listed earlier in this section

Fourth: appoint a project director

You, along with the utility owner/operator (or registered professional engineer) and all other employers involved in the work, must identify one person who will direct the implementation of the procedures. That person must have the authority to stop work at any time to ensure safety.

Fifth: reconsider your plan if a problem arises

The danger of operating a crane close to a power line cannot be overemphasized. Procedures that may appear adequate at the beginning of a job may not be adequate in practice. For example, if electricity arcs from the line to the equipment, whatever precautions are being taken are not sufficient. Therefore, if there is any indication that the procedures being followed are inadequate to protect workers, you must safely stop operations and either develop new, more protective procedures or have the utility owner/operator de-energize and visibly ground or relocate the power line before resuming work.